Boss Hog Extra® : Woven Wire MESH Flooring

Boss Hog Extra®

Woven Steel

Wire Flooring

J&L has been providing the hog production industry with Boss Hog® woven wire mesh flooring for decades. Through the years, we have listened to the requests of our customers and taken the opportunity to use our resources and current technology to search for ways to improve woven steel wire flooring. The outcome is an enhanced and refined product, now known as Boss Hog Extra®.

Boss Hog Extra® is J&L’s answer to providing a long-lasting hog flooring that will hold up against the harsh demands of the hog production industry. Environmental testing completed by an independent test lab has shown Boss Hog Extra® lasting over 15 times longer than our standard open woven wire mesh floor when exposed to an aggressive salt spray (ASTM B117) environment. Results suggest not only will it outlast other woven wire mesh floors, but found it to be comparable to other steel woven wire mesh flooring that is post-coated for protection (check out our technical bulletin that discusses the testing and results).

Boss Hog Extra® is made from high-quality round steel wire, which is drawn in-house and galvanized using our proprietary coating method. This premium wire is an essential component in durable steel woven wire mesh flooring, providing superior strength, corrosion resistance, and long-lasting performance for agricultural and industrial applications. At J&L, we oversee this operation to ensure full control over the production of the wire and coating process so that our customers receive only the best quality woven wire mesh flooring available. Each woven wire hog mesh floor is a product of the United States, designed and assembled with pride.

Construction

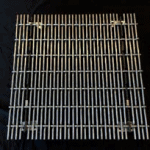

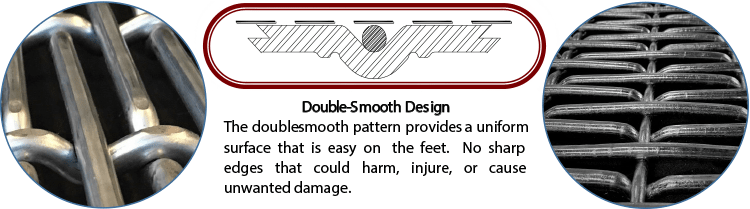

Our woven steel wire flooring uses our patented “double smooth” design. This patented design provides for excellent traction since skid-free footing means fewer injuries. In addition, our flooring does not contain ridges, laps, or sharp edges along its surface, an unwanted characteristic found in some competitor’s products.

The open woven pattern of the steel wire permits the space necessary for the passage of waste making clean up effortless. Unlike polymer hog flooring where bacteria can become trapped within the surface of the polymer itself, a steel wire surface is less likely to trap these harmful bacteria. Flushing and cleaning of the woven wire is easy, and the flooring is designed to keep the sows and piglets dry reducing the spread of enteric diseases. J&L uses two sizes of steel wire to manufacture Boss Hog Extra®: a heavy 3-gauge, or a super-heavy 1/0-gauge zinc-coated steel wire.

Call our friendly sales team at 866.777.8607 to place an order and benefit from the features Boss Hog Extra® hog flooring has to offer.

Self-Supported

Flooring

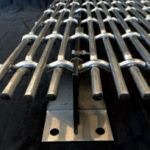

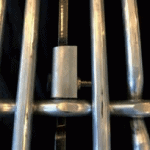

An innovative development for the hog flooring industry is J&L’s newly designed and developed Boss Hog Extra® Self-Supported Floor. The concept, to remove the necessity of purchasing additional frames and supports needed to secure the flooring and to reduce the costs associated with the additional time needed to assemble and procure the ancillary parts. In their place, J&L incorporates supports into the hog flooring. These supports are snapped into place using the woven wires comprising the swine floor. To further assure that the supports remain secured and in place, a locking mechanism is incorporated restricting the supports from movement and becoming displaced.

Why Consider Our New Self-Supported Floor?

There are many reasons for choosing Boss-Hog Extra® Self-Supported Flooring over the competitor’s offerings. When considering the ease of installation alone, one can quickly grasp the potential savings in time and money, but there are many other advantages as well. Following are just a few items to consider before your next purchase.

Our proprietary galvanized coating process found on Boss-Hog Extra® provides a coating that maintains better uniformity in thickness and overall consistency. This promotes a smoother wire surface for improved wear characteristics. The coating on wires that undergo the hot dipped method found in our competitor’s products will typically be found to be more inconsistent and rougher affecting the durability of their product.

Boss-Hog Extra® woven wire flooring does not contain welds that can deteriorate and break after time. Each wire is continuous from start to finish as it is drawn through our loom and woven into the finished product.

The supports making up the self-supported flooring incorporate the necessary strength found in heavy duty woven wire flooring to assure that the surface stays level with no bows making it easier to obtain the proper fit when installing equipment.

Our floors are available in a variety of sizes, up to six (6) feet wide by twelve (12) feet long and come in either 5/16” wire. Our larger sections offer a faster installation saving additional time and money.

Woven wire flooring is a practical solution for farrowing and nursery applications. Their ease of flushing and cleaning in addition to our double-smooth design makes them less likely to trap bacteria.

Will the floor supports provide the necessary strength?

J&L Wire

J&L Wire tested our self-supported flooring in accordance with the American National Standards Institute (ANSI) standard MH26.2, “Design, Testing, and Utilization of Welded-Wire Rack Decking.” The same test we subject our Wire Decking to. This evaluation provides critical data on the floor’s overall strength, including deflection and load capacity. Detailed information on the testing process is available in our Technical Bulletin, “Determining Deck Load Capacities.”

Testing to ANSI MH26.2 revealed the following results for our welded wire flooring:

0.30” floor deflection at 1,000 lbf

0.55” floor deflection at 2,000 lbf

Based on these results, we confidently conclude that our self-supported flooring, reinforced with wire flooring, not only meets but exceeds the necessary strength requirements, ensuring superior durability and reliability to fully satisfy our customers’ expectations