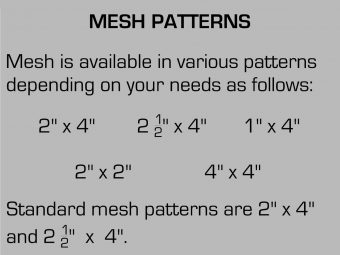

COMMON WIRE MESH DECKING CONFIGURATIONS

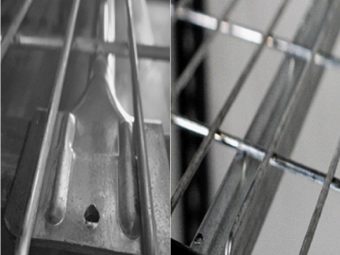

STANDARD WATERFALL (with standard channel)

This wire mesh design features an edge bent 90° that overlaps the horizontal support beam of the pallet rack to help secure the wire mesh deck in place.

INSIDE WATERFALL (with standard channel)

Ideal for tight spaces, this welded wire mesh design has edges bent 90° to rest within the step beam. Also ideal for use when the front or rear beams must be open for bar coding.

SINGLE RIVET SHELVING (Bulk Storage)

Designed for 5/8” step beams, these wire mesh decks provide extra capacity for bulk storage. Underside wires enable you to add additional wire shelves underneath the main shelf to further increase the amount of storage space and weight capacity.

DOUBLE RIVET SHELVING (Bulk Storage)

J&L’s wire decks for bulk storage are designed with waterfalls in the front and rear for safety when hand loading. These waterfalls prevent clothing from catching and injury to hands