Warehouse storage strategies in the United States are shifting as operators handle higher order volumes, labor shortages, and stricter safety and fire code requirements. One of the largest trends in warehouse storage solutions is improving what already exists.

Rather than replacing entire systems, many facilities are upgrading storage infrastructure and operational tools to improve efficiency, visibility, and compliance while extending the life of existing assets.

The following five trends represent the most impactful changes shaping warehouse storage and operations nationwide.

- Selective pallet racking modernized with wire decking and structural supports

- Increased use of wire decking for safety, visibility, and fire compliance

- Storage layouts informed by mobile-first WMS platforms

- Fulfillment-driven designs emphasizing vertical space and dense storage

- Stronger focus on load stability and damage prevention

Let’s dive deeper:

- Modernizing Selective Pallet Racking with Wire Decking and Structural Supports

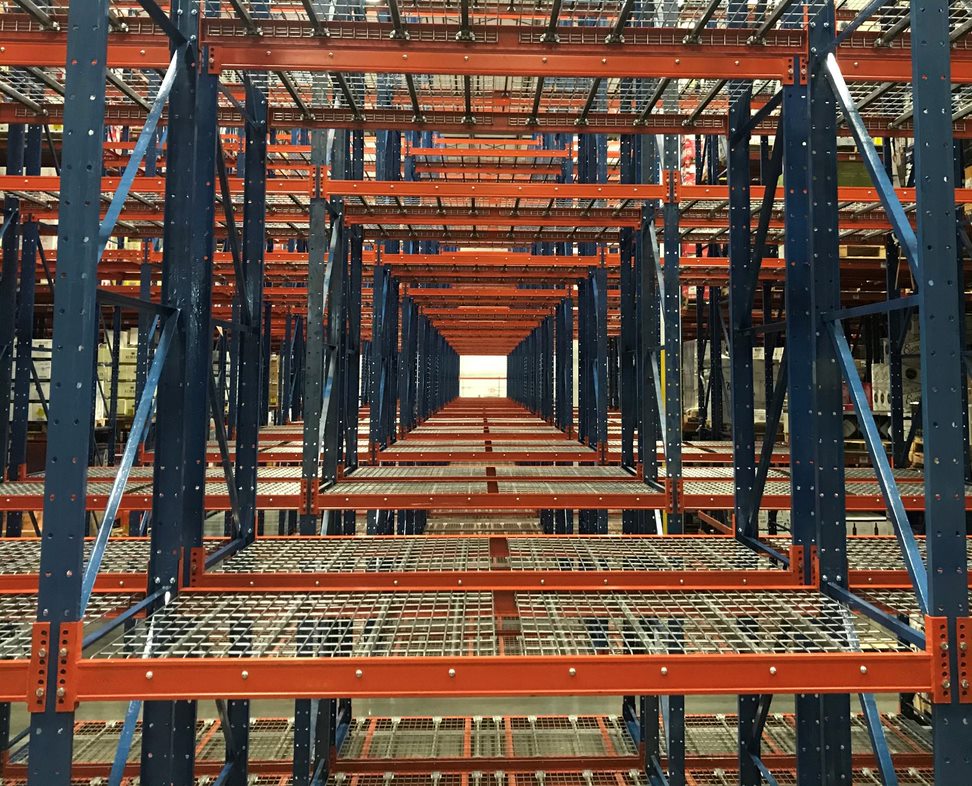

Selective pallet racking remains the most widely deployed storage system in U.S. warehouses due to its flexibility and direct pallet access. A key trend is not replacing selective racking, but reinforcing and modernizing it to meet higher load requirements and safety standards.

Wire decking and pallet rack supports are increasingly added to traditional beam-and-upright systems to create stable storage surfaces, improve airflow, and enhance load distribution. Open decking designs allow sprinkler systems to operate as intended while reducing debris accumulation and improving visual inspection of inventory.

Pallet supports and integrated structural mesh components also help reduce pallet deflection and minimize product fall-through, particularly in high-density or mixed-load environments.

As facilities aim to increase vertical storage while maintaining compliance, these upgrades have become standard in modern selective pallet rack installations. J&L Wire is a to supplier of wire decking and rack support components used for these types of system enhancements.

- Increased Use of Wire Decking for Safety, Visibility, and Fire Compliance

Wire decking has become a core element of modern warehouse storage design, particularly in new construction and large-scale retrofits.

In the United States, over 60% of newly constructed warehouses utilized wire mesh decking for pallet racking systems, according to Market Reports World.

This adoption is driven by measurable operational and safety benefits. Wire decking improves visibility across racking systems, making it easier to identify damaged pallets, confirm inventory placement, and reduce picking errors. The open mesh design supports fire safety by allowing water from overhead sprinklers to pass through racks, improving coverage and reducing fire risk.

From an operations standpoint, wire decking offers flexibility for storing palletized and non-palletized items, requires less maintenance than solid shelving, and helps reduce dust and debris buildup. These advantages make it a practical, cost-effective solution for fast-moving distribution centers and regional warehouses alike.

- Warehouse Storage and Layouts Informed by Mobile-First WMS Platforms

Warehouse storage decisions are increasingly influenced by mobile-first warehouse management systems (WMS) that connect physical layouts with real-time operational data.

Modern WMS platforms are moving away from fixed, desktop-based software toward app-driven tools designed for use on standard smartphones and tablets.

These systems support faster onboarding, clearer location management, and improved picking accuracy by digitizing storage zones and workflows.

Tools such as PULPO WMS focus on creating digital representations of warehouse layouts to guide storage and picking decisions, while platforms like ShipHero are commonly used in high-volume e-commerce operations to manage replenishment and picking activity directly from mobile devices.

Visual inventory tools such as Sortly are also influencing how smaller warehouses organize storage by emphasizing photos, QR codes, and simplified item identification.

At the enterprise level, platforms like Infios (formerly Körber) reflect a trend toward tighter integration between storage systems and automation, including robotics and voice-directed picking.

Overall, these applications are shaping how warehouses label, configure, and optimize storage space, reinforcing the link between physical infrastructure and digital operational control.

- Storage Designs Influenced by High-Volume Fulfillment Operations

Large-scale fulfillment operations have influenced storage strategies across the logistics industry. Companies operating at significant scale, such as Amazon, have helped set expectations for dense storage configurations, rapid inventory access, and system reliability.

As a result, many warehouses are designing storage systems that maximize vertical space, support faster picking paths, and reduce travel time between locations. While not every facility operates at the same volume, storage layouts increasingly reflect principles proven in high-throughput fulfillment environments, particularly for e-commerce, omnichannel, and third-party logistics operations, including dense pallet storage configurations that require higher-capacity rack support.

- Greater Emphasis on Load Stability and Damage Prevention

As warehouses handle heavier loads and higher-value inventory, load stability has become a central storage concern. Uneven pallets, mixed SKUs, and automated material handling equipment increase the risk of deflection, rack damage, and product loss.

To mitigate these risks, facilities are reinforcing storage systems with pallet supports, structural mesh components, and engineered decking solutions that improve weight distribution and reduce stress on rack beams.

These enhancements support safer operations, reduce inventory damage, and align with insurance and regulatory expectations, especially in high-density storage environments.

Outlook for U.S. Warehouse Storage

Warehouse storage trends in the United States point toward incremental system upgrades rather than full replacements. Enhancing selective pallet racking, expanding wire decking adoption, and integrating mobile-first management tools allow facilities to improve safety, efficiency, and compliance while controlling capital costs.

As logistics demands continue to grow, these trends will remain central to how warehouses design, manage, and optimize their storage systems. For more than 40 years, J&L Wire has supported these evolving storage needs by supplying high-quality galvanized wire decking and structural wire solutions to warehouse, logistics, and material handling operations nationwide from our locations in Minnesota, South Carolina, and Texas.