Your Guide to Choosing the Best Wire Mesh Decking Solutions for Warehouse Racks

Selecting wire mesh decking for pallet racking systems is not just a purchasing decision. It affects load performance, safety, fire code compliance, visibility, and long-term maintenance. Warehouse managers comparing wire deck and wire decking options often encounter significant performance differences depending on how the deck is manufactured and finished.

This article explains how

Galva-Deck® differs from standard wire decking and why those differences matter in real warehouse environments

What Is Galva-Deck?

Galva-Deck is a

galvanized wire mesh deck engineered specifically for pallet rack systems. Unlike standard painted or powder-coated wire decking, Galva-Deck uses a zinc-galvanized finish that is metallurgically bonded to the steel.

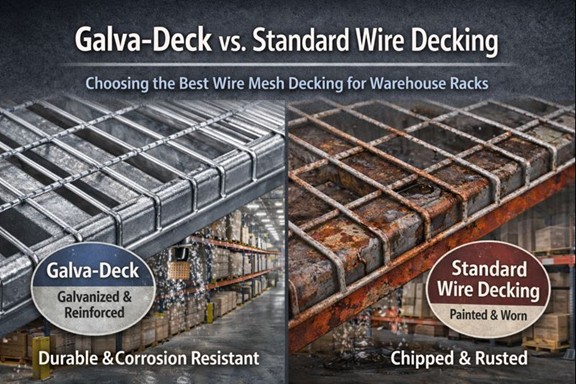

From a materials perspective, this distinction is important. Painted coatings sit on the surface and can chip or wear through. Galvanizing bonds zinc to the steel, creating corrosion resistance that remains effective even when the surface is scratched or worn by erosion/extended use.

Galva-Deck uses welded wire with built-in support channels that spread weight evenly across the rack beams, helping the decking stay flat instead of sagging under heavy loads.

Why Finish Type Matters in Warehouse Environments

Wire decking is exposed to conditions that are often underestimated. Forklift vibration, pallet friction, humidity, and temperature swings all contribute to coating failure over time.

In facilities with painted wire decking, common issues include surface flaking, rust formation at weld points, and reduced lifespan in areas with frequent pallet movement. Galvanized wire decking resists these failure points because the zinc coating protects exposed steel even after minor surface damage.

This makes galvanized decking particularly relevant in:

- Distribution centers with high pallet turnover

- Facilities that store metal or moisture-sensitive goods

- Warehouses operating in humid or unconditioned spaces

Industry Visibility and Trade Evaluation

When warehouse operators and system integrators evaluate the best wire mesh decking suppliers for warehouse racks, the focus is typically on verifiable performance, manufacturing consistency, and real-world application data rather than marketing claims.

National industry venues like

MODEX serve as a primary forum for this type of evaluation, bringing together warehouse operators, system integrators, safety professionals, and engineers responsible for specifying pallet rack components.

J&L Wire’s participation as a

listed exhibitor at MODEX 2026 places its wire decking alongside other load-bearing storage solutions, allowing industry professionals to review material finishes, structural design, and application suitability in the context of real warehouse requirements rather than marketing claims.

In that setting, Galva-Deck stands out because its reinforced construction, corrosion-resistant finish, and consistent load performance align directly with the durability, safety, and long-term reliability warehouse professionals are evaluating on the show floor.

For those evaluating wire decking options in person, J&L Wire representatives will be available to discuss Galva-Deck’s design and application considerations.

Real-World Use Scenarios

In a regional distribution center handling consumer goods, wire decks are frequently contacted by pallets during loading and retrieval. Over time, painted decks show wear along the wire intersections and support channels. Galva-Deck, by contrast, maintains structural integrity and corrosion resistance despite repeated contact.

In facilities governed by fire safety codes, wire mesh decking is preferred over solid decking because it allows sprinkler water penetration. Galva-Deck maintains open-mesh performance while also reflecting more ambient light, improving visibility at rack levels without additional lighting.

Cold storage and food-adjacent warehouses also benefit from galvanized wire decking, where condensation and wash-down conditions accelerate corrosion on coated alternatives.

Galva-Deck vs. Standard Wire Decking

The table below highlights functional differences that warehouse operators commonly evaluate when selecting

wire mesh decking suppliers for warehouse racks.

| Performance Area |

Galva-Deck |

Standard Wire Decking |

| Corrosion resistance |

Galvanized zinc bond protects steel even after abrasion |

Dependent on surface coating integrity |

| Finish durability |

High resistance to chipping and wear |

Paint or powder coat can flake or peel |

| Load distribution |

Engineered channel supports tailored to rack spans |

Often generic channel designs; channel material is fabricated to precise strength specifications. |

| Visibility & light |

Reflective galvanized finish improves light penetration |

Lower reflectivity |

| Fire code compatibility |

Open mesh supports sprinkler discharge |

Open mesh but coating degradation can affect longevity |

| Maintenance over time |

Minimal surface degradation |

Often requires earlier replacement |

How Galva-Deck® Fits Within a Broader Racking System

Wire decking does not function in isolation. It works in combination with pallet racks,

pallet supports, and load-rated structural components.

J&L Wire manufactures complementary solutions that are often specified together in warehouse designs, including pallet supports and structural wire components used in rack safety systems. From an engineering standpoint, sourcing decking and supports from the same manufacturer helps ensure compatibility across load ratings and beam spans.

Relevant internal resources include

pallet rack accessories, pallet supports, and

industrial wire solutions, all accessible through the J&L Wire site.

FAQs

How does J&L Wire cloth compare to other wire cloth brands?

J&L Wire manufactures wire cloth and wire decking in the United States and controls its welding, galvanizing, and quality processes in-house. Compared to imported or commodity brands, this typically results in more consistent load ratings, better coating performance, and tighter dimensional tolerances.

Is galvanized wire decking always better than painted wire decking?

Not in every environment, but in warehouses with moisture, abrasion, or heavy pallet movement, galvanized decking generally lasts longer and requires less maintenance.

Does wire mesh decking affect fire safety compliance?

Yes. Open wire mesh allows sprinkler water to reach lower rack levels more effectively than solid decking, which is why wire decking is often preferred in fire-code-regulated facilities.

Can wire decking be customized for different rack sizes?

Yes. Wire decking is commonly manufactured in different widths, depths, wire gauges, and channel configurations to match specific rack systems and load requirements.

What should warehouses consider when choosing wire mesh decking suppliers?

Key factors include load ratings, finish durability, compatibility with existing racks, manufacturing consistency, and long-term performance rather than upfront cost alone.